As a new material, zirconium-containing material has been developed rapidly in the recent ten years. In the field of refractories, natural zirconium-containing mineral raw materials and artificial extraction or synthesis of zirconium oxide and composite oxide raw materials have also been widely used to produce a variety of excellent zirconium-containing refractories.

There are about 50 kinds of zirconium minerals known to us, among which more than 20 are common. Zirconium mineral raw materials for industrial use are mainly zirconium quartz, oblique zircon, hafnium zircon, and anisotropic zircon. With the development of science and technology, zirconium oxides and composite oxides have been extracted or synthesized by various processing methods and applied in various fields.

Zirconium-containing raw materials are widely used in the refractory industry, which is mainly because of their high melting temperature and strong chemical stability. They have good corrosion resistance to metal melt, slag, or glass fluid, as well as good thermal shock resistance, so they can be used as refractories for glass kiln, metallurgical industry refractories, and so on.

Zirconium-containing refractories are mainly used in the melting part, superstructure, side wall, and fluid hole of glass melting furnace. Refractories made from zirconium materials are widely used in the metallurgical industry and can be divided into zirconium quartz products, zirconia products, aluminum zirconia carbon products, zirconium carbon products, calcium zirconate products, zirconium boride products, zirconia modified refractories, etc.

Zirconium quartz products have the characteristics of high-temperature resistance, good resistance to acid slag, small erosion, slight viscosity of slag, small thermal expansion coefficient, good thermal shock stability, etc., which can be better used as the lining of steel drums, but also can be masonry in the direct impact of steel, slag line parts, around the nozzle and other key parts.

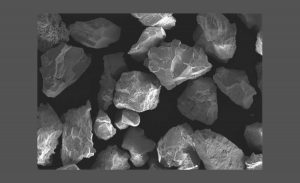

The main raw material for the production of zirconium quartz products is zirconium quartz concentrate, and some clay, pyrophyllite, chromium oxide, and zirconia can be also added as needed. In general, zirconium particles are small in size and are not suitable for direct brick production, which requires the raw materials of zirconium quartz and part of the combined clay to be mixed, semi-dry pressed, and made into the blank. There are a wide variety of zirconia products and many molding methods, such as mud pouring method, hot pressing method, machine pressing method, isostatic pressure method, etc.

Aluminum-zirconium carbonaceous product is developed on the basis of aluminum-carbonaceous product, and it can be used as sliding nozzle brick of ladle (or tundish), long nozzle, plug rod, immersed nozzle, and so on. Compared with the corresponding aluminum carbon material, aluminum zirconium carbon products have better oxidation resistance, thermal shock stability, erosion resistance, and higher strength, so the service life is longer. The addition of a certain amount of zirconia in refractory materials such as jade-quality, high-alumina, magnesium-calcium, aluminum-magnesium, magnesium-chromium and magnesium-carbon commonly used in the metallurgical industry can improve the chemical stability, thermal shock stability and strength of these materials. In these materials, zirconia is usually introduced in the form of zircon sand and zirconia.

The specific production process is usually the same or slightly changed before modification. Generally speaking, zirconium-containing raw materials have been widely used in the field of refractories due to their excellent properties, and their application scope will be more and more extensive.

Please visit http://www.samaterials.com for more information.