Introduction

Hafnium, a transition metal known for its remarkable properties, is commonly used in the form of wire for various high-tech and industrial applications. This article explores the key specifications of hafnium wire and its diverse applications across multiple industries.

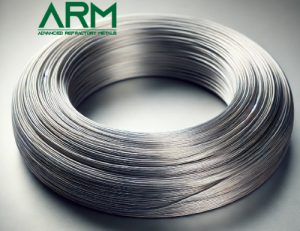

Key Specifications of Hafnium Wire

Hafnium wire specifications vary depending on the intended application. However, some general specifications include:

- Purity: Hafnium wire is typically available in purity levels of 99.5%, 99.9%, and 99.95%, with higher purity levels being used in applications requiring exceptional corrosion resistance and neutron absorption.

- Diameter: The wire is available in various diameters, commonly ranging from 0.1 mm to 3.0 mm. Custom diameters can be produced based on specific application needs. Send us an inquiry if you are interested.

- Tensile Strength: Hafnium wire can achieve tensile strengths of up to 300 MPa, particularly when cold-drawn.

- Density: 13.31 g/cm³, a relatively high density, contributing to its strength and durability in demanding applications.

- Melting Point: 2,233°C, making it suitable for high-temperature environments.

- Coating: Some hafnium wires may be coated with materials like platinum to enhance oxidation resistance.

Applications of Hafnium Wire

Hafnium wire is utilized across a broad range of industries due to its unique properties. Here are some of the key applications:

1. Nuclear Industry

Control Rods in Nuclear Reactors: Hafnium’s exceptional ability to absorb neutrons without forming long-lived radioactive isotopes makes it an ideal material for control rods in nuclear reactors. These rods are critical for controlling the fission process and maintaining reactor safety. The high melting point and corrosion resistance of hafnium wire further ensure its reliability in the harsh environment of a nuclear reactor.

Related reading: 4 Uses of Hafnium

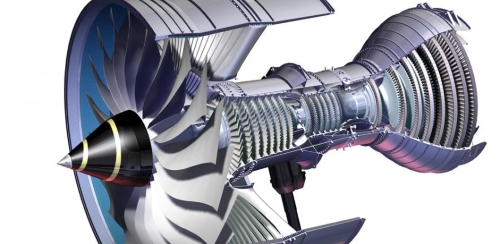

2. Aerospace Industry

Jet Engine Components: In aerospace applications, hafnium wire, particularly in alloyed form (e.g., Hafnium-Zirconium alloy), is used in jet engine components that operate at temperatures exceeding 1,000°C. The wire’s oxidation resistance and strength at high temperatures make it suitable for these critical applications, where failure is not an option.

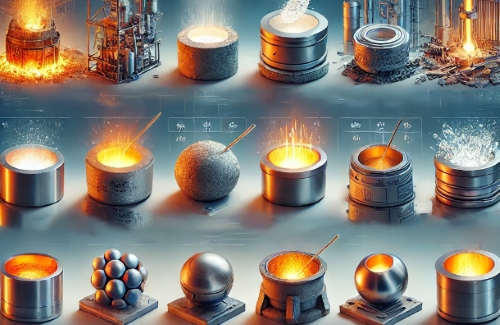

3. Industrial Heating Elements

Furnace Heating Elements: Oxide-dispersion strengthened (ODS) hafnium wire is used in industrial furnaces that operate at extremely high temperatures, often above 1,800°C. The fine oxide particles in the wire enhance its resistance to thermal creep, ensuring that the heating elements maintain their structural integrity over prolonged periods of use.

4. Automotive Industry

Catalytic Converters: Hafnium wire coated with platinum is used in automotive catalytic converters. The platinum coating enhances the wire’s resistance to oxidation and chemical attack from the corrosive gases in exhaust systems. This application is crucial for reducing harmful emissions from vehicles, contributing to environmental sustainability.

5. Medical Field

Surgical Implants and Clips: Annealed hafnium wire is employed in the production of surgical clips and other medical implants. The annealing process improves the wire’s ductility, allowing it to be easily shaped and manipulated during surgical procedures. Additionally, hafnium’s biocompatibility makes it safe for use within the human body.

6. Electronics and Semiconductor Industry

Gate Electrodes in Semiconductors: Hafnium wire is used in the semiconductor industry for gate electrodes in field-effect transistors (FETs). Its high dielectric constant helps reduce leakage currents, improving the performance and efficiency of electronic devices. The use of hafnium in semiconductor applications is vital for the advancement of microelectronics.

7. Scientific Research

High-Temperature Thermocouples: In scientific research, hafnium wire is used in thermocouples for measuring extremely high temperatures. The wire’s stability at high temperatures ensures accurate and reliable temperature measurements, which are critical in experiments and industrial processes.

| Industry | Application | Key Benefits |

| Nuclear

Industry |

Control Rods in Nuclear Reactors | Absorbs neutrons,

high melting point, corrosion resistance |

| Aerospace

Industry |

Jet Engine Components | Oxidation resistance,

high-temperature strength |

| Industrial

Heating Elements |

Furnace Heating Elements | Resistance to

thermal creep, structural integrity at high temperatures |

| Automotive Industry | Catalytic Converters | Oxidation resistance,

reduces harmful emissions |

| Medical Field | Surgical Implants and Clips | Ductility,

biocompatibility |

| Electronics &

Semiconductor Industry |

Gate Electrodes in Semiconductors | High dielectric

constant, improves electronic performance |

| Scientific

Research |

High-Temperature Thermocouples | Stability at

high temperatures, accurate temperature measurements |

Advanced Refractory Metals (ARM) provides an extensive selection of high-quality refractory metal products and heat-resistant materials. ARM offers low pricing and great lead times on all our metals and alloys, and we’re capable of supplying custom materials per any specs/drawings you provide us with.

Conclusion

With a high melting point, corrosion resistance, and neutron absorption capability, Hafnium Wire has become essential in nuclear reactors, aerospace engines, industrial furnaces, automotive components, medical implants, and advanced electronics. Its specifications can be tailored to suit specific requirements, ensuring that it continues to play a vital role in modern technology and industry.

[2]

[2]