What is Metal?

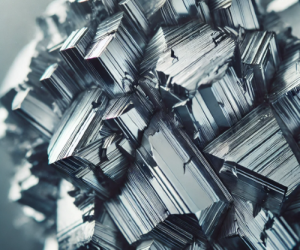

Metals are a distinct category of elements known for their conductive properties, malleability, ductility, and generally high density. With the exception of mercury, metals are typically solid at room temperature and exhibit a lustrous appearance. These materials are integral to numerous industries, including construction, manufacturing, and electronics, due to their unique characteristics. A comprehensive understanding of both the physical and chemical properties of metals is essential for selecting the appropriate material for specific applications.

Physical Properties

- Electrical and Thermal Conductivity: Metals are excellent conductors of electricity and heat, attributed to the presence of delocalized electrons within their atomic structure. For example, copper has an electrical conductivity of approximately 59.6 × 10^6 S/m, making it a preferred choice for electrical wiring, while aluminum, with a conductivity of around 37.7 × 10^6 S/m, is widely used in various thermal applications.

- Malleability: This property refers to the ability of metals to deform under compressive stress without fracture. Metals such as gold and silver are highly malleable, enabling them to be shaped into thin sheets, which is advantageous in electronics and jewelry manufacturing.

- Ductility: Ductility is the capacity of a metal to be drawn into wires. For instance, copper and aluminum can be extruded into long, thin wires without breaking, making them suitable for applications requiring high tensile strength, such as power transmission lines.

- Density: Metals generally possess high density, a measure of mass per unit volume. For example, lead has a density of approximately 11.34 g/cm³, while aluminum has a density of 2.70 g/cm³. This property is crucial in industries where weight considerations are paramount, such as aerospace.

- Hardness: Hardness indicates a material’s resistance to deformation and scratching. Hard metals, such as tungsten (hardness around 8.5 on the Mohs scale) and chromium, are utilized in cutting tools and machinery due to their durability.

- Luster: The reflective quality of metals, or luster, is a result of their ability to reflect light. This characteristic not only enhances aesthetic appeal but also contributes to applications in decorative elements and surface coatings.

- Melting and Boiling Points: Metals typically exhibit high melting and boiling points. Tungsten, for instance, has an exceptional melting point of approximately 3,422°C, making it ideal for high-temperature applications, such as aerospace components.

Chemical Properties

- Reactivity: Metals display varying reactivities with other substances. For example, alkali metals, such as sodium and potassium, are highly reactive with water, while noble metals like gold and platinum exhibit minimal reactivity, making them suitable for use in corrosive environments.

- Oxidation: Metals are prone to oxidation when exposed to air and moisture. Iron, for instance, oxidizes in the presence of oxygen and water, forming iron oxide (rust). Understanding oxidation rates is essential for selecting metals for outdoor applications or environments prone to corrosion.

- Corrosion Resistance: Certain metals, such as stainless steel and aluminum, possess inherent corrosion resistance due to the formation of a protective oxide layer. This property is crucial for applications in construction, marine, and chemical processing industries where exposure to harsh conditions is common.

- Alloy Formation: Metals can form alloys, which are mixtures of two or more elements that retain metallic properties. For example, steel, an alloy of iron and carbon, exhibits significantly enhanced strength compared to pure iron, making it suitable for structural applications.

- Acid-Base Behavior: Metals can react with acids, producing hydrogen gas and corresponding metal salts. For instance, zinc reacts with hydrochloric acid to yield zinc chloride and hydrogen. This property is significant in chemical processing and waste management applications.

Property Values of Common Metals

Understanding the specific properties of common metals aids in material selection for various applications. Here are some key property values:

– Aluminum:

– Density: 2.70 g/cm³

– Electrical Conductivity: 37.7 × 10^6 S/m

– Melting Point: 660°C

– Corrosion Resistance: High due to oxide layer

– Copper:

– Density: 8.96 g/cm³

– Electrical Conductivity: 59.6 × 10^6 S/m

– Melting Point: 1,085°C

– Malleability: Excellent

– Iron:

– Density: 7.87 g/cm³

– Electrical Conductivity: 10.0 × 10^6 S/m

– Melting Point: 1,538°C

– Reactivity: Prone to oxidation

– Stainless Steel (an alloy):

– Density: 8.00 g/cm³

– Electrical Conductivity: 1.4 × 10^6 S/m

– Melting Point: 1,400-1,500°C

– Corrosion Resistance: Very high

– Titanium:

– Density: 4.51 g/cm³

– Electrical Conductivity: 2.4 × 10^6 S/m

– Melting Point: 1,668°C

– Corrosion Resistance: Excellent in acidic environments

– Lead:

– Density: 11.34 g/cm³

– Electrical Conductivity: 4.5 × 10^6 S/m

– Melting Point: 327.5°C

– Hardness: Relatively soft

Conclusion

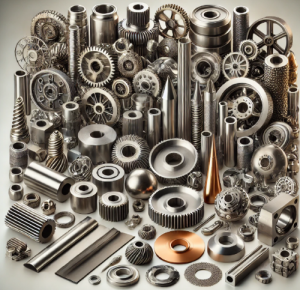

Metals are fundamental materials with a diverse array of applications due to their distinctive physical and chemical properties. Understanding these properties—such as conductivity, malleability, and corrosion resistance—enables engineers and manufacturers to select the most suitable metal for specific applications. The ability to create alloys further enhances the versatility of metals, making them indispensable across various industries. As technological advancements continue, the exploration of metal properties will drive innovation and improve material performance in an ever-evolving landscape. For more information, please visit Advanced Refractory Metals (ARM).