Introduction

Refractory metals, known for their exceptional resistance to heat and wear, include elements like tungsten, molybdenum, tantalum, niobium, and rhenium. Their unique properties make them critical in applications ranging from aerospace to medical devices. Let’s learn about their unique characteristics and understand why they’re valued in extreme-temperature and high-stress environments.

1. Melting Points: Withstanding Extreme Temperatures

Among refractory metals, tungsten holds the highest melting point at 3,422°C, followed closely by rhenium at 3,180°C and tantalum at 3,017°C. Molybdenum and niobium have lower melting points, at 2,623°C and 2,477°C, respectively, yet remain significantly higher than those of most other metals.

The high melting points of these metals are invaluable in aerospace applications, where materials must withstand extreme heat. For instance, tungsten is used in the throats of rocket nozzles, where temperatures reach thousands of degrees. The ability of tungsten and rhenium to retain their structure and resist melting under these conditions is critical to the reliability of aerospace and defense equipment.

2. Density and Mass for High-Strength Applications

Refractory metals like rhenium and tungsten exhibit high densities, with values of 21.0 g/cm³ and 19.3 g/cm³, respectively. In contrast, molybdenum (10.2 g/cm³) and niobium (8.6 g/cm³) are less dense, while tantalum’s density is 16.6 g/cm³, making it another heavyweight contender.

The dense nature of tungsten and rhenium is advantageous in radiation shielding and counterweights in precision equipment. For instance, tungsten shields are preferred over lead in portable X-ray machines due to their higher density, which allows for effective radiation blocking with less bulk, enhancing device portability.

3. Thermal Conductivity: Managing Heat Efficiently

Tungsten and molybdenum exhibit high thermal conductivity, with values of 174 W/m·K and 138 W/m·K, respectively. This makes them ideal for applications requiring efficient heat dissipation. Tantalum, niobium, and rhenium, however, have relatively lower thermal conductivities, making them less optimal in heat-intensive roles where rapid cooling is necessary.

High thermal conductivity is essential in electronics, where tungsten and molybdenum help manage heat generated by devices like semiconductors and high-power LEDs. Molybdenum’s use as a heat spreader in LED backplates, for example, helps prevent overheating, enhancing product lifespan and efficiency.

4. Corrosion Resistance: Stability in Reactive Environments

Tantalum is renowned for its resistance to corrosion, particularly in acidic environments, making it highly sought after in chemical processing. Niobium also exhibits good corrosion resistance, while tungsten and molybdenum are more prone to oxidation unless used in vacuum or inert atmospheres.

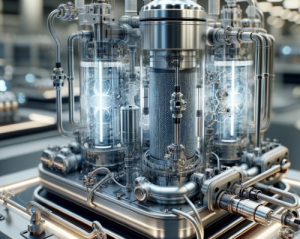

Tantalum is widely used in chemical processing for reaction vessels and pipes that come into contact with highly reactive or corrosive substances. Its ability to withstand acids, including hydrochloric and nitric acid, at high temperatures minimizes corrosion, thereby reducing maintenance costs and downtime.

5. Hardness and Wear Resistance

Tungsten and its alloy tungsten carbide are exceptionally hard, with Vickers hardness values reaching up to 2,200 HV. Molybdenum and tantalum are less hard but offer good resistance to abrasion in milder applications. Niobium and rhenium are softer by comparison, making them more suitable for less abrasive environments.

Tungsten carbide’s hardness makes it ideal for cutting tools and mining equipment that must endure constant wear. In the oil and gas industry, tungsten carbide-tipped drill bits significantly improve durability and reduce downtime by resisting wear from abrasive rock and soil.

6. Biocompatibility: Safe for Medical Use

Tantalum and niobium are biocompatible, meaning they are safe for implantation in the human body, while tungsten and molybdenum are more often avoided in medical implants due to concerns over biocompatibility and solubility.

Tantalum’s biocompatibility makes it a valuable material in medical implants and surgical tools, especially in bone replacements and spine implants, where it promotes bone in-growth. Additionally, niobium is used in pacemaker casings and dental implants, benefiting patients due to its compatibility with bodily tissues.

| Metal | Melting

Point (°C) |

Density

(g/cm³) |

Thermal

Conducti -vity (W/m·K) |

Vickers

Hardness (HV) |

Notable

Property |

| W | 3422 | 19.3 | 174 | 343–460 | Highest

melting point |

| Mo | 2623 | 10.2 | 138 | 220–320 | High

thermal conductivity |

| Ta | 3017 | 16.6 | 57 | 200–400 | Corrosion

resistance |

| Nb | 2477 | 8.6 | 53 | 100–150 | Biocompa

-tibility |

| Re | 3180 | 21 | 48 | 245–300 | High

cost, rare |

Conclusion

Refractory metals offer properties unmatched by conventional materials. Tungsten’s unmatched melting point and thermal conductivity, tantalum’s corrosion resistance and biocompatibility, and rhenium’s rare strength retention make these metals indispensable. By comparing their unique properties, engineers and scientists can make informed choices to meet the rigorous demands of modern technology and industrial applications. For more refractory metal products, please check Advanced Refractory Metals (ARM).