Introduction

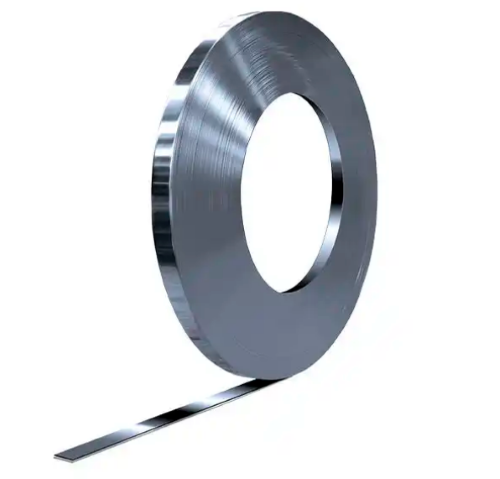

For centuries, the quest for substances that combine strength with exceptional resistance to corrosion has led to significant advancements. Among these materials, the zirconium strip stands out for its superior corrosion resistance. It marks a significant leap forward in extending the longevity and reliability of equipment across various industries.

This article delves into the corrosion resistance of zirconium strips. It also focuses on zirconium’s applications and the future outlook of this remarkable material.

Unveiling the Properties of Zirconium Strip

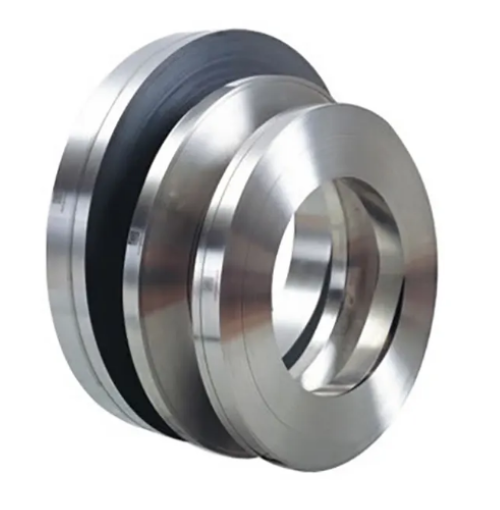

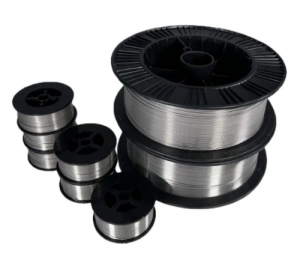

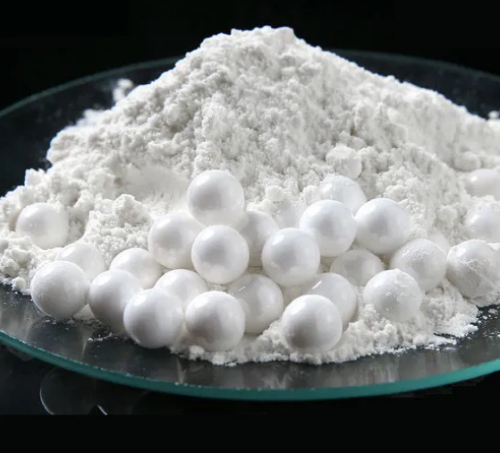

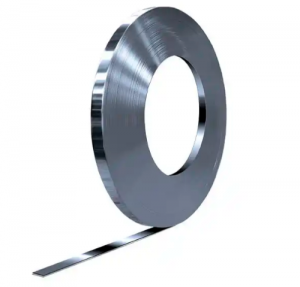

Zirconium is a lustrous, grey-white, strong transition metal. It is renowned for its corrosion resistance. When fashioned into strips, it offers a combination of durability, flexibility, and a formidable barrier against corrosive agents.

This resistance is primarily due to the formation of a thin, stable oxide layer on its surface when exposed to oxygen. That oxide layer effectively seals the metal from further attack by most acids and alkalis.

Industrial Applications: A Spectrum of Uses

The unique properties of the zirconium strip have led to its widespread adoption across multiple sectors. Here are some key areas where its impact is most pronounced:

–Chemical Processing Industry

In environments where exposure to harsh chemicals is a daily occurrence, equipment longevity is a constant challenge.

Zirconium strips are useful in the construction of pipes, valves, and reactors. Their resistance to corrosion significantly reduces maintenance costs and prevents contamination of sensitive reactions.

Related reading: Zirconium Strip in Chemical Processing and Petrochemicals

–Nuclear Reactors

Zirconium comes with a low neutron absorption cross-section. It has become ideal for nuclear reactors, where it is used in cladding fuel rods. The corrosion-resistant nature of the zirconium strip ensures the integrity of the reactor’s core components and enhances safety and efficiency.

–Medical Devices

The strip also stands out for its biocompatibility and corrosion resistance. It is suitable for various medical implants and devices. Its use in this field ensures that the implants remain safe and effective over time, without reacting adversely with bodily fluids.

–Aerospace and Defense

In aerospace and defense, Zr’s high strength-to-weight ratio and corrosion resistance are invaluable. Components made from zirconium strips can withstand the extreme conditions encountered in these applications. Such uses range from the corrosive nature of aviation fuels to the high-temperature environments of jet engines.

Advantages over Other Materials

Zirconium strip offers several advantages over traditional corrosion-resistant materials like stainless steel and titanium.

–Corrosion Resistance: Zirconium vs. Stainless Steel

- Zirconium: It exhibits superior corrosion resistance in most acidic environments, particularly in hydrochloric acid, sulfuric acid, and other aggressive media where stainless steel would typically fail.

- Stainless Steel: While stainless steel is known for its corrosion resistance, its performance heavily depends on the alloy composition and the environment it’s exposed to. In chloride-containing environments or highly acidic conditions, certain grades of stainless steel can suffer from pitting, crevice corrosion, or stress corrosion cracking.

–Corrosion Resistance: Zirconium vs. Titanium

- Zirconium: Similar to titanium, zirconium’s corrosion resistance is attributed to a protective oxide layer that forms on the surface. However, zirconium’s layer is even more effective in certain acidic conditions. It offers better protection than titanium in environments where titanium might be prone to corrosion.

- Titanium: Titanium’s excellent corrosion resistance comes from a passive oxide film that forms on its surface. It performs exceptionally well in seawater and chlorinated environments, as well as in the presence of most acids. However, at high temperatures or in the presence of certain acids (like hydrofluoric acid or concentrated sulfuric acid), titanium’s corrosion resistance can be compromised.

The Future of Zirconium Strip

The increasing demand for materials that can ensure the longevity and reliability of industrial equipment in corrosive environments is driving research into enhancing the properties of zirconium strips.

- Innovations in alloying techniques aim at improving its strength and corrosion resistance even further.

- Moreover, the development of cost-effective manufacturing processes is expected to make zirconium strips more accessible for a wider array of industries, from renewable energy to water treatment.

Conclusion

Zirconium strips offer industries a solution to one of their most persistent challenges. With impressive corrosion resistance, it gains applications in chemical processing, nuclear reactors, medical devices, and aerospace.

As research continues to unlock new potentials for this material, the Zr strip is set to become an even more integral component of industrial applications in the years to come. It promises a future where materials are not only stronger but also more resilient against the relentless forces of corrosion. For more information, please check Advanced Refractory Metals (ARM).