Introduction

Hafnium (Hf) is a unique transition metal with properties that make it indispensable in nuclear technology. Its remarkable ability to absorb neutrons has led to its widespread use in nuclear reactors, where it plays a critical role in controlling nuclear reactions. Hafnium’s high melting point, corrosion resistance, and compatibility with extreme environments make it ideal for use in the nuclear industry, especially in applications that demand high reliability and performance.

Properties of Hafnium that Benefit Nuclear Applications

1. High Neutron Absorption Cross-Section:

– One of hafnium‘s most critical properties in nuclear applications is its high neutron absorption cross-section. This means it can capture or absorb neutrons efficiently, which is crucial for controlling nuclear fission reactions. By absorbing excess neutrons, hafnium helps prevent uncontrolled reactions, allowing nuclear reactors to operate safely.

Further reading: 4 Uses of Hafnium | The Applications of Hafnium and Hafnium Alloys

2. High Melting Point:

– Hafnium has a melting point of approximately 2,233°C (4,051°F), making it one of the most heat-resistant metals. This property is essential in nuclear reactors, where materials are exposed to intense heat. Hafnium’s ability to withstand high temperatures ensures stability and longevity, even under the extreme conditions present in nuclear reactors.

3. Corrosion Resistance:

– Hafnium exhibits excellent corrosion resistance, particularly in the presence of hot water and steam, which are common in nuclear reactors. This resistance to oxidation and corrosion extends the lifespan of reactor components and minimizes the need for frequent maintenance or replacement.

4. Chemical Compatibility with Other Reactor Materials:

– Hafnium is chemically compatible with other materials commonly used in nuclear reactors, such as zirconium. This compatibility is essential for preventing reactions that could weaken reactor components or compromise safety.

Key Applications of Hafnium in the Nuclear Industry

1. Control Rods in Nuclear Reactors:

– Primary Function: The primary use of hafnium in nuclear technology is in control rods, which are crucial for regulating nuclear reactions. Control rods are inserted or withdrawn from the reactor core to control the fission process by absorbing neutrons. Hafnium’s high neutron absorption capacity makes it ideal for this purpose, as it effectively moderates the reaction rate.

– Enhanced Safety: Hafnium control rods help maintain the stability of the reactor, preventing it from becoming supercritical (where the reaction rate would accelerate uncontrollably). By adjusting the position of hafnium control rods, operators can control the rate of fission, ensuring a stable and safe energy output.

2. Nuclear Waste Management:

– Neutron Shielding: Hafnium’s neutron absorption properties are valuable in the storage and management of spent nuclear fuel and other radioactive waste. When used as a neutron shield, hafnium can absorb stray neutrons emitted by nuclear waste, reducing the radiation risk and enhancing the safety of waste storage facilities.

– Containment Systems: Hafnium can also be used in certain containment systems, where it helps to manage radiation levels and prevent the spread of radioactive materials.

3. Advanced Nuclear Reactors:

– Research Reactors and Experimental Facilities: Hafnium is also used in advanced reactor designs and research reactors, where precise control over neutron levels is required. In these environments, hafnium’s reliability and neutron absorption capabilities allow scientists to perform research under controlled and safe conditions.

– Next-Generation Reactors: As nuclear technology evolves, hafnium is expected to play a role in the development of next-generation reactors, such as small modular reactors (SMRs) and advanced breeder reactors. Its properties align well with the high safety and efficiency standards required in modern reactor designs.

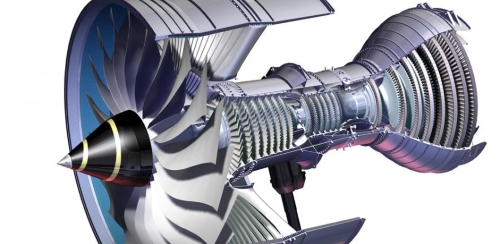

4. Nuclear Submarines and Marine Reactors:

– Compact Reactors: Hafnium is used in the control rods of compact reactors designed for naval vessels, including nuclear-powered submarines. In these reactors, space constraints demand materials that provide maximum efficiency and safety in a compact form. Hafnium’s neutron-absorbing properties and durability make it well-suited for these applications, where reliability is paramount.

Advantages of Using Hafnium in Nuclear Technology

- Enhanced Safety and Control: Hafnium’s strong neutron absorption controls fission rates, preventing reactor overheating and ensuring safe operations.

- Durability in Extreme Conditions: High melting point and corrosion resistance allow hafnium to withstand intense heat and pressure, reducing maintenance needs and downtime.

- Compatibility with Reactor Materials: Works well with zirconium, commonly used in fuel cladding, enabling efficient fission control without chemical conflicts.

- Extended Reactor Lifespans: Resistant to corrosion and radiation, hafnium supports longer-lasting reactor components, enhancing safety and efficiency over time.

Challenges and Considerations

Despite its benefits, there are challenges associated with the use of hafnium in nuclear technology:

- Availability and Cost:

Hafnium is relatively rare and is usually extracted as a byproduct of zirconium refinement. The separation process is complex and costly, as hafnium and zirconium are chemically similar. This scarcity and high extraction cost make hafnium an expensive material, which can limit its availability for widespread use in nuclear technology.

- Processing and Handling:

Hafnium is challenging to work with due to its high melting point and reactivity at elevated temperatures. Specialized equipment and techniques are required to process hafnium into usable forms, adding to the overall cost and complexity of production.

- Environmental and Health Risks:

Hafnium, especially in powdered form, can pose fire hazards. Additionally, while hafnium is not highly toxic, it should be handled with care to prevent exposure to hazardous compounds that may form during processing. Safety protocols are essential when handling and processing hafnium, particularly in the nuclear industry.

The Future of Hafnium in Nuclear Technology

As nuclear technology advances, the role of hafnium is expected to grow. New reactor designs, such as small modular reactors (SMRs) and generation IV reactors, require materials that offer high performance, safety, and durability. Hafnium’s properties make it suitable for these advanced designs, particularly in applications where precise control over neutron levels is essential. Additionally, research into hafnium-based alloys and composites may lead to materials with enhanced properties, expanding the potential applications of hafnium in the nuclear field.

Furthermore, hafnium’s role in radiation shielding and waste management could become increasingly important as the nuclear industry seeks safer and more efficient ways to handle radioactive waste. By incorporating hafnium into containment and storage solutions, nuclear facilities can improve safety while reducing the environmental impact of nuclear waste.

Conclusion

Hafnium is an invaluable material in the nuclear industry, where its neutron absorption capabilities, high melting point, and corrosion resistance make it essential for controlling and maintaining safe nuclear reactions. Used primarily in control rods, hafnium helps regulate fission processes, ensuring the stability and safety of nuclear reactors.

While challenges related to availability, cost, and processing exist, hafnium’s advantages in high-temperature and high-radiation environments make it a critical component of nuclear technology. For more information, please check Advanced Refractory Metals (ARM).

[2]

[2]