In the vast expanse of materials shaping modern industries, Zirconium 702 has carved its niche as a versatile and indispensable player, particularly in aerospace and chemical processing sectors. Renowned for its exceptional properties, Zirconium 702 alloys are making remarkable contributions to both realms, revolutionizing components and equipment for enhanced performance and durability.

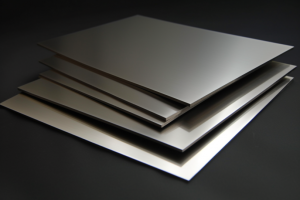

Aerospace engineering demands materials that can endure the most extreme conditions, from high temperatures to mechanical stresses. Zirconium 702 alloys rise to this challenge with their exceptional thermal stability and mechanical strength. Jet engines, the heart of modern air travel, rely on Zirconium 702 components for their ability to withstand intense heat and pressure. From turbine blades to exhaust nozzles, Zirconium 702 alloys contribute to the efficiency and reliability of aerospace propulsion systems.

Beyond the skies, Zirconium 702 alloys have also found their home in chemical processing industries. Their corrosion resistance is a standout feature, allowing them to thrive in environments fraught with aggressive acids and alkalis. Reactor vessels, pipes, and valves that handle corrosive substances benefit from the robust protection provided by Zirconium 702 components, ensuring extended service life and reduced maintenance requirements.

The marriage of Zirconium 702’s corrosion resistance and high-temperature stability makes it an ideal candidate for chemical processing equipment that operates under harsh conditions. In the realm of petroleum refining, Zirconium 702 plays a crucial role in catalytic processes, where it maintains its structural integrity and performance even in the presence of corrosive catalysts and high temperatures.

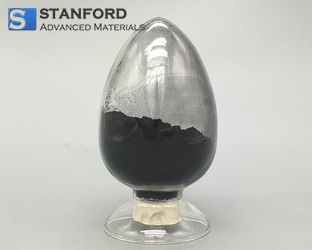

In addition to its innate properties, ongoing research and innovation are driving advancements in Zirconium 702 materials. Coating technologies are being explored to enhance the already impressive corrosion resistance, expanding the range of applications in both aerospace and chemical sectors.

As we shift towards a future that demands sustainable practices, Zirconium 702 alloys are poised to contribute further to the aerospace and chemical industries. Their ability to withstand harsh environments, coupled with continuous research, positions Zirconium 702 as a material that will continue to push the boundaries of engineering possibilities.

In summary, Zirconium 702 alloys have emerged as versatile champions in aerospace and chemical processing. Their thermal stability, mechanical strength, and corrosion resistance are instrumental in revolutionizing aircraft propulsion and chemical equipment. As technology evolves and industries strive for efficiency and sustainability, Zirconium 702 remains a beacon of innovation, shaping the future of aerospace and chemical engineering.

For more information about zirconium products, please visit https://www.samaterials.com/.