What Is Melting Point?

The melting point of a metal is the temperature at which it changes from a solid to a liquid state. At this specific temperature, the metal’s internal structure breaks down, allowing the atoms to move freely and form a liquid. The melting point is a fundamental physical property that varies widely among different metals. It is crucial in various industrial and manufacturing processes, such as casting, welding, and alloy production, where precise temperature control is necessary.

What Affects the Melting Points of Metals?

The melting point of a metal is influenced by several factors, each contributing to the stability and bonding strength within the metal’s structure:

- Atomic Structure:

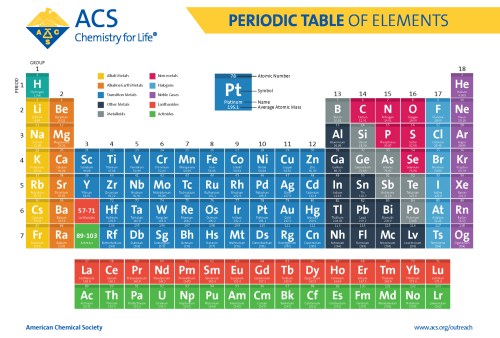

The arrangement and bonding of atoms in a metal significantly impact its melting point. Metals with closely packed atoms and strong metallic bonds tend to have higher melting points. For instance, transition metals, which have more complex electron configurations, generally exhibit higher melting points compared to alkali metals.

- Interatomic Forces:

The strength of the forces between atoms in a metal, including metallic bonds and van der Waals forces, determines how much energy is required to break these bonds and transition the metal to a liquid state. Stronger interatomic forces result in higher melting points.

- Purity of the Metal:

Impurities in a metal can disrupt its atomic structure and bonding, usually leading to a decrease in melting point. Pure metals typically have higher melting points compared to their alloys or impure forms.

- Pressure:

The melting point of metals can change under different pressure conditions. For instance, adding elements with different atomic sizes or electronegativities can disrupt the metal lattice, potentially lowering the melting point.

- Crystal Structure:

Metals crystallize in various structures such as body-centered cubic (BCC), face-centered cubic (FCC), and hexagonal close-packed (HCP). The type of crystal structure affects the metal’s melting point. For instance, metals with an HCP structure often have higher melting points due to their more efficient atomic packing.

What Are High Melting Point Metals?

High melting point metals are those that can withstand extremely high temperatures without transitioning to a liquid state. These metals are essential in applications requiring materials to maintain structural integrity under intense heat. Some of the most notable high melting point metals include:

Tungsten has the highest melting point of all metals at 3,422°C (6,192°F). It is used in applications like light bulb filaments, welding electrodes, and in aerospace and defense industries for its exceptional heat resistance.

With a melting point of 3,186°C (5,767°F), rhenium is used in high-temperature turbine engines and as an alloying element to enhance the properties of other high melting point metals.

Tantalum’s melting point is 3,017°C (5,463°F). It is used in the electronics industry for capacitors and high-power resistors, as well as in medical implants due to its biocompatibility.

Molybdenum melts at 2,623°C (4,753°F). It is utilized in steel alloys to improve strength and resistance to corrosion and high temperatures.

With a melting point of 2,468°C (4,474°F), niobium is used in superconducting materials and high-temperature alloys.

Which Metal Has the Highest Melting Point?

Tungsten holds the record for the highest melting point of all metals, at a staggering 3,422°C (6,192°F). This exceptional property makes tungsten indispensable in industries that require materials to perform reliably at extremely high temperatures. Tungsten’s high melting point is attributed to its strong metallic bonds and densely packed atomic structure. It is commonly used in applications such as:

- Electrical Components: Tungsten is used in light bulb filaments, X-ray tubes, and other electrical contacts where high temperatures are involved.

- Aerospace and Defense: Tungsten is used in rocket engine nozzles, heating elements in high-temperature furnaces, and in military applications for its density and high-temperature resilience.

- Manufacturing Tools: Tungsten is a key component in the production of cutting tools and wear-resistant surfaces, ensuring longevity and performance under intense operating conditions.

Conclusion

Understanding the melting points of metals is fundamental in material science and engineering. The melting point indicates the temperature at which a metal transitions from solid to liquid, influenced by factors like atomic structure, interatomic forces, purity, pressure, and crystal structure.

High melting point metals, such as tungsten, rhenium, tantalum, molybdenum, and niobium, play critical roles in applications demanding superior heat resistance. Among these, tungsten stands out with the highest melting point, making it essential in numerous high-temperature industrial processes. For more heat resistant materials, please check Advanced Refractory Metals (ARM).