Introduction

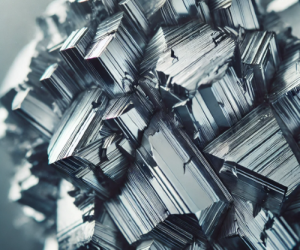

Niobium is a metal with special properties that make it important in aerospace. It is strong, resists heat, and does not rust easily. These features make niobium perfect for the harsh conditions in airplanes and spacecraft.

What Makes Niobium Special?

Niobium has several key traits that make it useful in aerospace:

- High Heat Resistance: Niobium can handle very high temperatures. It melts at 2,468°C (4,474°F), so it works well in places like jet engines that get extremely hot.

- Corrosion Resistance: Niobium does not rust or break down easily, even when exposed to tough environments. This is crucial for parts that need to last a long time, such as those in space or at high altitudes.

- Strength: When mixed with other metals, niobium makes them stronger. This means parts made from niobium alloys can endure a lot of stress without breaking or losing shape.

- Lightweight: Niobium has a good strength-to-weight ratio, meaning it can help make strong but lightweight parts for aircraft and spacecraft.

Related reading: 10 Important Uses of Niobium

Niobium in Jet Engines

Jet engines are incredibly hot and put parts under extreme stress. Niobium alloys are often used in engine components like turbine blades. These blades must stay strong while spinning at high speeds and facing high temperatures.

Niobium makes sure the blades do not melt or break under these tough conditions. By using niobium, engineers can make engines more efficient and longer-lasting.

Niobium in Rockets

Rockets face even more heat and pressure than jet engines. When rockets launch, their engines burn fuel at extreme temperatures to create thrust. Niobium alloys are often used in the rocket nozzles, which direct the hot gases out of the engine. Since niobium can handle these extreme conditions, it helps prevent the rocket parts from melting or warping.

In addition, niobium resists “thermal creep,” which is when materials slowly deform from constant high heat. This is critical for long space missions, where parts need to maintain their shape over time.

Niobium in Spacecraft

Spacecraft are exposed to very harsh environments. Temperatures can swing from freezing cold to boiling hot. Spacecraft also face radiation and lack the protection that Earth’s atmosphere provides. Niobium alloys are used in the structural parts of spacecraft because they are strong, lightweight, and resistant to both heat and corrosion.

Niobium’s strength and resistance help ensure that spacecraft can survive the extreme conditions of space without breaking down. Its lightweight nature also helps reduce the overall weight of the spacecraft, which is crucial for successful launches.

Superconductivity in Aerospace

Niobium also has the ability to become “superconductive.” This means it can carry electricity without any resistance when it is cooled to very low temperatures. In aerospace, superconductivity could lead to advances in power systems, propulsion, and even magnetic levitation technology. Although this is still a developing area, niobium’s role in superconductivity makes it important for future technologies in space travel.

Future Uses of Niobium in Aerospace

As aerospace technology advances, the need for materials like niobium will grow. The industry is constantly pushing for lighter, stronger, and more heat-resistant materials. Niobium will continue to be used in aircraft and spacecraft because of its unique properties.

In the future, niobium could also be used in new types of power systems, advanced engines, and lighter spacecraft. Its ability to work in extreme conditions makes it an ideal material for the next generation of aerospace technologies.

Conclusion

Niobium is a key material in aerospace because it is strong, heat-resistant, and lightweight. It plays an important role in jet engines, rockets, and spacecraft, ensuring that these machines can operate under extreme conditions. As aerospace technology continues to evolve, niobium will remain a vital material in the industry. Its ability to handle heat and stress while staying strong makes it perfect for the future of flight and space exploration. For more metal products, please check Advanced Refractory Metals (ARM).