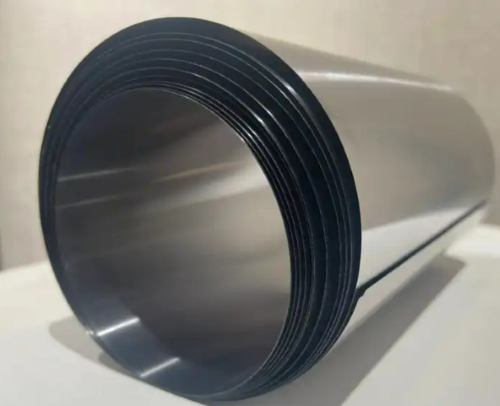

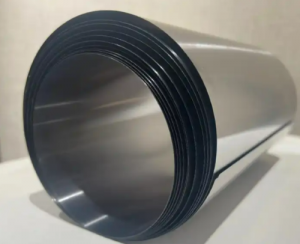

Zirconium, a silvery-white transition metal, might not be a household name like gold or iron, but it is an essential element in a wide range of industries. From its role in aerospace to its applications in dentistry, zirconium offers a unique blend of properties that make it both fascinating and highly useful. Here’s a deep dive into the world of zirconium.

[1]

[1]

1. The Basics of Zirconium

Zirconium, with the chemical symbol Zr and atomic number 40, is a member of the transition metals in the periodic table. Its name originates from the Arabic word “zargun,” meaning “gold-colored,” which refers to the zircon gemstones that contain zirconium. Despite its name’s connection to gold, zirconium itself is typically silver-gray.

– Atomic Weight: 91.22

– Melting Point: 1,855°C (3,371°F)

– Boiling Point: 4,409°C (7,968°F)

Zirconium is abundant in the Earth’s crust, ranking as the 20th most common element. However, it is not found in its pure form; instead, it is extracted from minerals like zircon (ZrSiO₄) and baddeleyite (ZrO₂).

2. Its Unique Properties

Zr is known for its remarkable physical and chemical properties, which make it invaluable in numerous applications:

– High Corrosion Resistance: Zr resists corrosion by acids, alkalis, and seawater, making it ideal for environments where durability is critical.

– Heat Resistance: It has a high melting point, making it suitable for high-temperature applications.

– Low Neutron Absorption: This property is particularly significant in nuclear reactors, where zirconium is used to contain nuclear fuel.

– Biocompatibility: Zr is non-toxic and hypoallergenic, which is why it’s used in medical and dental implants.

3. Uses of Zirconium

A. Nuclear Industry

Zirconium’s low neutron absorption cross-section makes it indispensable in the nuclear industry. It is used to manufacture cladding for nuclear fuel rods, ensuring the safe containment of radioactive materials while allowing neutrons to pass through.

B. Aerospace and Defense

Thanks to its strength and heat resistance, it is used in jet engines, spacecraft, and military applications. Its ability to withstand extreme conditions makes it a critical material for advanced engineering.

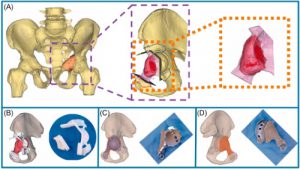

C. Dental Applications

Zirconium oxide, commonly known as zirconia, is a popular material for dental crowns and bridges. Its biocompatibility, durability, and aesthetic resemblance to natural teeth make it a preferred choice in modern dentistry.

D. Jewelry and Gemstones

The gemstone zircon, which contains zirconium, is often used as a diamond substitute due to its brilliance and clarity. Cubic zirconia, a synthetic material made from zirconium dioxide, is a popular, affordable alternative to diamonds.

E. Industrial Applications

Zr is used in manufacturing heat exchangers, pumps, and valves for chemical processing due to its resistance to corrosion. Additionally, it is employed in making ceramics and refractories for high-temperature processes.

4. Historical Background

Zirconium was first isolated in 1824 by the Swedish chemist Jöns Jakob Berzelius, who used potassium to reduce zirconium tetrachloride. However, its applications remained limited until the 20th century, when its unique properties were fully understood. The development of nuclear technology during World War II significantly increased interest in zirconium, leading to its widespread use in reactors.

5. Fun Facts About Zirconium

– Fireworks Sparkle: Zr is used in pyrotechnics to create brilliant flashes of light. Its high reactivity with oxygen makes it perfect for generating sparks.

– Space Exploration: Zirconium alloys are used in spacecraft construction due to their ability to withstand extreme temperatures and stress.

– Ancient Origins: Zircon, the mineral from which zirconium is extracted, is one of the oldest materials on Earth. Some zircon crystals have been dated to over 4.4 billion years old.

– Non-Magnetic Nature: Zr is non-magnetic, making it useful in devices and environments where magnetism could interfere with operations.

– Dental Perfection: Zirconia dental implants are so strong that they are often referred to as “ceramic steel.”

Conclusion

Zirconium’s unique properties and diverse applications make it an unsung hero of modern science and industry. From its role in enabling safe nuclear energy to its contribution to beautiful dental restorations and sparkling jewelry, zirconium is a fascinating element that continues to shape our world. As research and technology advance, zirconium’s importance is only set to grow, solidifying its place as a material of the future. For more information, please visit Advanced Refractory Metals (ARM).

Reference:

[1]

Zirconium. (2024, October 30). In Wikipedia. https://en.wikipedia.org/wiki/Zirconium