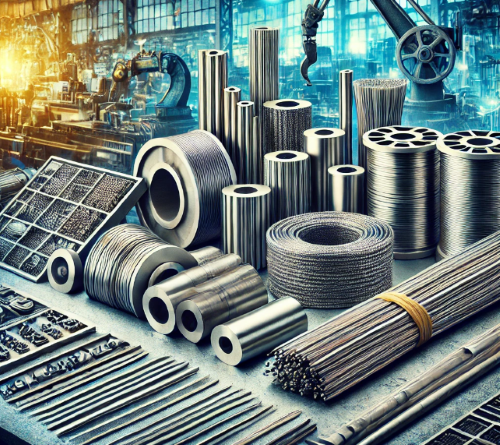

Rhenium is known for its outstanding properties, such as high melting point, excellent corrosion resistance, and remarkable strength at high temperatures. These characteristics make rhenium powder indispensable in a range of industries, particularly in high-performance and extreme conditions. Here are some typical applications of rhenium powder:

1. Aerospace and Jet Engine Components

Rhenium powder is widely used in the aerospace industry, particularly in the production of high-temperature superalloys. These alloys are critical for jet engine components like turbine blades, combustors, and nozzles. Rhenium enhances the heat resistance and strength of nickel-based alloys, allowing them to maintain their structural integrity at temperatures exceeding 1,000°C. This makes rhenium essential for aircraft engines, rocket propulsion systems, and other aerospace applications.

- Example: Rhenium-containing superalloys, such as those used in turbine blades, improve engine performance and efficiency by enabling engines to operate at higher temperatures.

2. Catalysts in Chemical Processing

Rhenium powder is a key material in catalytic processes, especially in the petroleum and chemical industries. It is often used as a catalyst or catalyst modifier in the production of high-octane gasoline, hydrogenation reactions, and the reforming of hydrocarbons. Rhenium’s high surface area and catalytic activity make it effective in facilitating these reactions, especially in processes that involve heavy oils, sulfur compounds, or other challenging substances.

- Example: Rhenium-based catalysts are used in the hydrocracking of petroleum to produce higher-quality fuel and other petrochemicals.

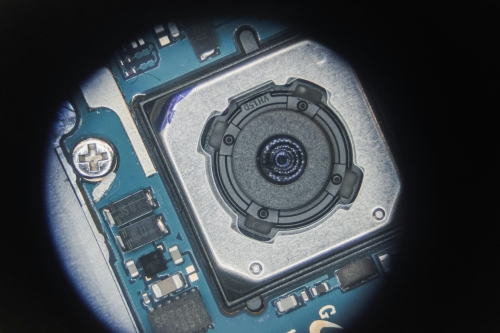

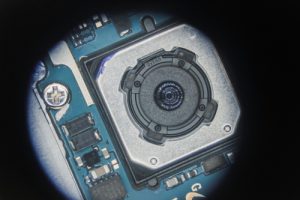

3. Electronics and Semiconductor Industry

Rhenium powder is used in the electronics industry for thin-film coatings and as a component in electrical contacts. It offers excellent conductivity and resistance to wear, making it ideal for applications where reliability and longevity are essential. Rhenium powder is also used in the production of thermocouples, which measure temperature in harsh environments.

- Example: Rhenium is used in the production of contact materials for electrical relays and switches, ensuring consistent and long-lasting performance in critical electronics.

4. Manufacturing of Electrical Contacts and Filaments

Due to its high melting point and resistance to oxidation, rhenium powder is used to create electrical contacts, filaments, and anodes. These components are found in devices where electrical conductivity is essential, but the operating environment involves high temperatures or corrosive elements. Rhenium’s unique properties allow it to perform reliably in such conditions, which is why it is favored for critical applications in high-temperature electrical systems.

- Example: Rhenium filaments are used in certain high-precision instruments and sensors, including those found in space probes.

5. Rhenium Alloys in High-Temperature Applications

Rhenium is often alloyed with other metals like tungsten, molybdenum, and platinum to improve their properties at high temperatures. Rhenium-containing alloys are used in applications that require extreme heat resistance, such as rocket nozzles, high-temperature furnaces, and electrical contacts. These alloys benefit from rhenium’s ability to enhance ductility, strength, and stability at elevated temperatures.

- Example: Rhenium-tungsten alloys are used in components for the aerospace industry that need to withstand temperatures above 3,000°C, such as parts of rocket engines.

6. Superconducting Materials

Rhenium is also involved in the development of superconducting materials. When combined with other metals, it can form superconducting compounds with enhanced electrical conductivity. This has promising applications in the production of magnetic resonance imaging (MRI) equipment and other medical devices that rely on high-performance superconductivity.

- Example: Rhenium is used in the production of superconducting magnets for use in MRI machines, where high magnetic fields are required for precise imaging.

7. Hydrogen Fuel Cells

In the emerging field of hydrogen energy, rhenium powder plays a role in the development of fuel cell technology. Rhenium’s catalytic properties make it useful in hydrogen production and in the reaction processes within fuel cells. By improving the efficiency of these reactions, rhenium powder contributes to the development of clean, renewable energy sources.

- Example: Rhenium-based catalysts are used in hydrogen production processes, such as water splitting, which is vital for sustainable hydrogen fuel cell technology.

8. Thin Films and Coatings

Rhenium powder is used to create thin films and coatings, especially in applications that require resistance to heat, oxidation, or radiation. These films are typically applied to components exposed to extreme conditions, such as space exploration materials, rocket components, and high-performance automotive parts.

- Example: Rhenium coatings are used on aerospace components to protect them from high-speed atmospheric friction and prevent oxidation at high altitudes.

9. Optical Instruments

Due to its high melting point and resistance to heat and corrosion, rhenium powder is used in the production of precision optical instruments, such as mirrors and lenses. These instruments must maintain their performance under extreme conditions, making rhenium an ideal material for parts that are subjected to high temperatures and intense radiation.

- Example: Rhenium is used in the construction of space-based telescopes and other optical instruments designed for high-altitude or space missions.

Conclusion

Rhenium powder plays a critical role in a variety of industries where high performance, high temperature, and corrosion resistance are essential. From aerospace to petrochemicals, electronics, and renewable energy, rhenium’s unique properties make it an indispensable material for advanced technologies. As industries continue to evolve, the demand for rhenium powder in high-performance applications is expected to grow, driving innovation and contributing to the development of new technologies across multiple sectors. For more information, please check Advanced Refractory Metals (ARM).