Zirconia (ZrO2) ceramics are special ceramics with unique physical and chemical properties, and their applications in electronic ceramics, functional ceramics and structural ceramics have developed rapidly. However, the fatal shortcomings of zirconia ceramic materials are brittleness, low reliability, and low repeatability, which seriously affect its application range. Only by improving the fracture toughness of zirconia ceramics, strengthening the material and improving its reliability and service life, can zirconia ceramics truly become a widely used new material.

Toughening technology of zirconia ceramics has been a hot spot in ceramics research. At present, ceramic toughening methods mainly include phase change toughening, particle toughening, fiber toughening, self-toughening, diffusion toughening, synergistic toughening, and nano-toughening, etc.

Phase toughening

Phase toughening refers to the metastable tetragonal phase t-ZrO2 undergoing a phase change under the action of the stress field at the crack tip, forming a monoclinic phase, resulting in volume expansion, thereby forming compressive stress on the crack, hindering crack growth, and increasing the role of toughness. In addition, external conditions (such as laser shock, fatigue fracture toughness, low temperature, grain size and content, critical transition energy, etc.) have a great effect on the phase toughening of zirconia ceramics. If the phase transition produces large stress and volume changes, the product is prone to fracture. Therefore, the influence of external factors on the phase toughening of zirconia ceramics should be avoided during production.

Particle toughening

Particle toughening refers to the method of using particles as a toughening agent and adding it to ZrO2 ceramic powder. Although its effect is not as good as whiskers and fibers, if the particle type, particle size, content and matrix material are properly selected, there is still a certain strong effect. The advantage is that it is simple and easy to implement, and it will also improve the high-temperature strength and high-temperature creep performance while toughening. The toughening mechanism of particle toughening mainly includes the refinement of matrix grains and crack-turning bifurcation.

Fiber toughening

The principle of fiber and whisker toughening is that the crystal close to the crack tip adds closing stress to the crack surface due to deformation, offsets the external stress at the crack tip, and passivates the crack propagation, thereby strengthening the toughness. In addition, when cracks are propagated, the frictional force must be overcome when the columnar crystals are pulled out, which also plays the role of toughening.

Self-toughening

Due to the existence of columnar crystals, cracks will be deflected during the fracture process of zirconia ceramics, which will change and increase the path of crack growth, thereby passivating the cracks, increasing the crack growth resistance and achieving toughening.

Diffuse toughening

Diffusion toughening mainly refers to the toughening of the ceramic matrix by the tetragonal ZrO2 particles. In addition to the phase toughening mechanism, there is also a diffusion toughening mechanism of the second phase particles. Before cracks propagate, the internal residual strain energy of the ceramic itself must first be overcome to achieve the purpose of toughening.

Microcrack toughening

Micro-crack toughening refers to adding a tough material at the crack stress tip to cause micro-cracks to achieve the purpose of dispersing stress, reducing the force of crack advance, and thereby increasing the toughness of the material. When a material undergoes a phase transition, it often results in residual strain energy effects and microcracks. Therefore, the effect of phase transition toughening is significant.

Composite toughening

Composite toughening refers to the simultaneous use of several toughening mechanisms during the actual toughening of ZrO2 ceramics, thereby improving the toughening effect of ZrO2 ceramics. In the actual application process, the specific toughening mechanism is selected according to the different properties of the zirconia ceramic material to be prepared.

Nano toughening

At present, there are three main academic viewpoints of nano-toughening, namely: the theory of refinement, trans-crystalline, and “pinning”.

- The refinement theory believes that the introduction of nano-phases can suppress the abnormal growth of the matrix grains, refine the matrix structure uniformly, and improve the strength and toughness of the nano-oxide ceramic composites.

- The trans-crystalline theory holds that in nanocomposite materials, the matrix particles are densified with the nanoparticles as the core, and the nanoparticles are encapsulated inside the matrix grains to form an “intracrystalline” structure. In this way, the effect of the main grain boundary can be weakened, transgranular fracture is induced, and transgranular fracture instead of intergranular fracture occurs when the material is fractured, thereby improving the strength and toughness of the nano-zirconia ceramic composite material.

- The “pinning” theory believes that the nanoparticles existing in the grain boundaries of the matrix produce a “pinning” effect, which limits the occurrence of grain boundary slippage, pores, and creep. The enhancement of grain boundaries leads to the improvement of the toughness of nano-zirconia multiphase ceramic.

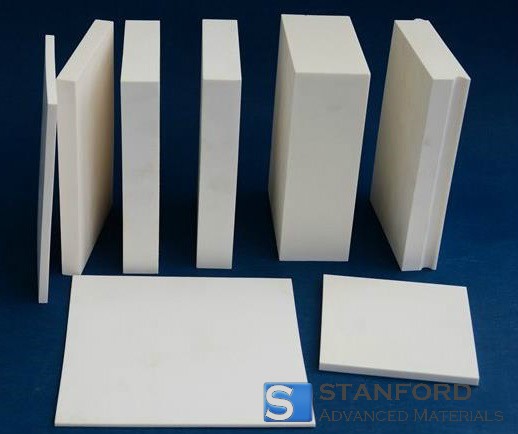

Stanford Advanced Materials supplies high-quality zirconium products to meet our customers’ R&D and production needs. Please visit https://www.samaterials.com/ for more information.