Introduction

Hafnium is a versatile transition metal with exceptional properties, such as high melting point, corrosion resistance, and excellent neutron absorption capabilities, finding applications ranging from nuclear energy to aerospace engineering and beyond. Here’s a more detailed look at its common uses:

1. Nuclear Reactors

– Usage: Hafnium is used in control rods, which are essential for regulating nuclear fission in reactors. The metal’s high neutron absorption cross-section (approximately 104 barns for thermal neutrons) makes it extremely effective in this role.

– Case: The VVER (Water-Water Energetic Reactor) series of nuclear reactors, widely used in Russia and several other countries, utilize hafnium in their control rods. This application is critical for maintaining reactor safety and controlling the power output.

Related reading: What Hafnium Is Used For?

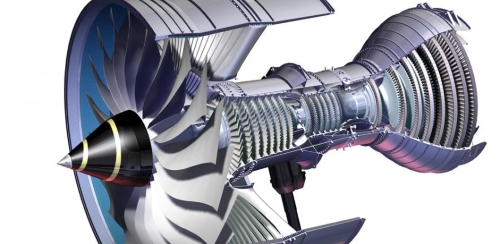

2. Aerospace Industry

– Usage: Hafnium is added to high-temperature superalloys used in jet engines and spacecraft components. These superalloys must withstand temperatures exceeding 1,500°C, where hafnium helps maintain structural integrity.

– Case: Pratt & Whitney’s PW4000 turbofan engines, used in Boeing 777 aircraft, incorporate hafnium in the nickel-based superalloys for turbine blades. This enhances their resistance to oxidation and thermal creep, thereby extending their operational lifespan.

3. Superalloys

[2]

[2]

– Usage: Hafnium is alloyed with nickel, cobalt, and other metals to create superalloys. These are crucial for parts like turbine blades, which operate at high temperatures and stress levels. Hafnium content in superalloys is typically between 0.5% to 2%. Even small amounts of hafnium can significantly improve the alloy’s mechanical properties and resistance to environmental degradation.

– Case: The Rolls-Royce Trent 1000 engine, used in Boeing 787 Dreamliners, uses hafnium-containing superalloys. These superalloys contribute to the engine’s efficiency and durability, which are critical for long-haul flights.

4. Plasma Cutting Tips

– Usage: Hafnium is used in the tips of plasma cutting torches, where it must withstand extreme heat and electrical currents. The addition of hafnium extends the lifespan of the torch tips by 5 to 10 times compared to copper tips. This translates into more precise cuts and reduced operational costs.

– Case: Hypertherm’s Powermax series plasma cutters use hafnium-tipped electrodes, which are known for their durability and efficiency in cutting through various metals, including steel and aluminum.

Related reading: Electrode Materials for Plasma Cutting Machines

5. Semiconductor Industry

– Usage: Hafnium oxide (HfO2) is utilized as a gate insulator in CMOS (complementary metal-oxide-semiconductor) technology, particularly in advanced microprocessors. Hafnium oxide’s dielectric constant (k ~ 25) is significantly higher than that of silicon dioxide (k ~ 3.9), which allows for the continued scaling down of transistor sizes while maintaining performance.

– Case: Intel introduced hafnium-based high-k dielectrics in their 45nm Penryn processors in 2007. This innovation helped reduce power leakage and allowed for more transistors to be packed into a smaller space, enhancing processing power and efficiency.

6. Corrosion-Resistant Coatings

– Usage: Hafnium is used to coat materials in harsh chemical environments, such as those found in the chemical processing industry. Hafnium coatings can resist temperatures up to 2,200°C and are highly resistant to acids and alkalis.

– Case: In the petrochemical industry, hafnium coatings are applied to components in catalytic cracking units, which operate under highly corrosive conditions. These coatings help extend the lifespan of the components, reducing downtime and maintenance costs.

7. Medical Applications

– Usage: Hafnium isotopes, particularly Hf-178, are used in cancer treatment through neutron capture therapy. Hf-178, when exposed to a neutron flux, emits beta particles and gamma rays that can be targeted at cancerous cells, minimizing damage to surrounding healthy tissue.

– Case: In experimental treatments at the Massachusetts General Hospital, hafnium-based compounds have been used in targeted radiation therapy for treating aggressive brain tumors, such as glioblastomas. The precise targeting afforded by hafnium isotopes offers a promising approach to improving patient outcomes.

8. Optical Coatings

– Usage: Hafnium dioxide (HfO2) is used in thin films for optical coatings, enhancing the durability and performance of lenses, mirrors, and other optical components. HfO2 has a high refractive index (~2.0 at 550 nm) and excellent transparency from the UV to the IR spectrum, making it ideal for multilayer coatings.

– Case: The Hubble Space Telescope’s primary mirror uses hafnium-based coatings to enhance its reflectivity and protect it from degradation due to exposure to cosmic radiation. This contributes to the telescope’s ability to capture high-resolution images of distant celestial objects.

These specific examples and data illustrate the vital role that hafnium plays in various high-tech and industrial applications, underlining its significance across multiple fields. For more information and Hafnium products, please check Advanced Refractory Metals (ARM).

Reference:

[1] University of Cambaige (2008, September 1). ‘Super’ superalloys: Hotter, stronger, for even longer. Retrieved August 15, 2024, from https://www.cam.ac.uk/research/news/super-superalloys-hotter-stronger-for-even-longer