The all-ceramic dental prosthesis has excellent mechanical properties, no gingival inflammation, and excellent biocompatibility, and it has no obstruction to X-ray rays. In addition, it has excellent wear resistance, corrosion resistance, and aesthetic properties of no gingival black edge and emulating natural teeth, all of these make it the first choice of dental repair materials.

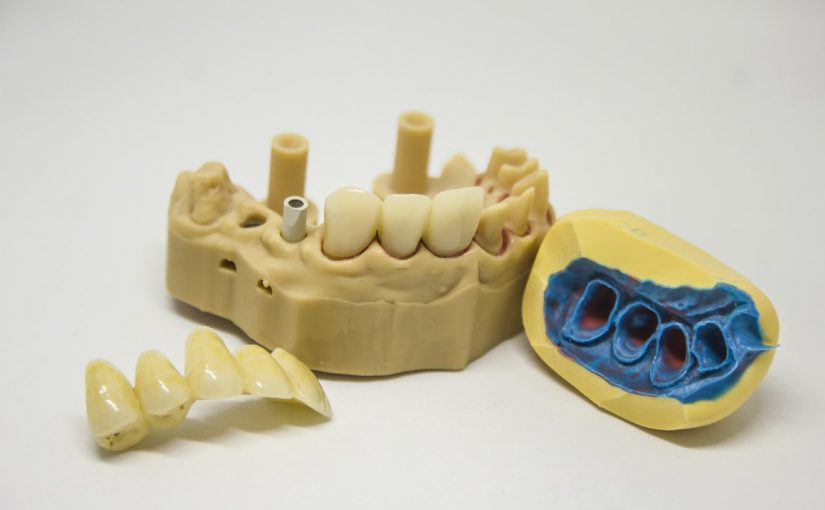

Zirconia ceramic teeth

At present, there are three kinds of materials used in all-ceramic dental restorations, namely, zirconia all-ceramic dental restorations, cast ceramic dental restorations and alumina all-ceramic dental restorations.

Among the three kinds of all-ceramic teeth, zirconia all-ceramic teeth are the strongest dental restorations. Its fracture toughness ratio is two or three times that of alumina all-ceramic, and it is not easy to break the teeth with it; secondly, it can be used for cosmetic dentistry and restoration of missing teeth. It can be used to repair multiple teeth, which can be used to repair even crowns, which can perfectly solve the problem that the strength of ceramic casting material is too poor to make continuous crown; moreover, its color is perfectly adjustable, so it can be used to make very realistic dentures.

Zirconia denture, as such an excellent product, should have been favored by the public. But zirconia restorations are expensive, costing thousands or even thousands of dollars for a single crown, which makes it unaffordable for ordinary people.

Why are zirconia ceramic teeth so expensive?

The main reason for the high price of zirconia ceramic teeth is that the overall production cost of zirconia teeth is really high.

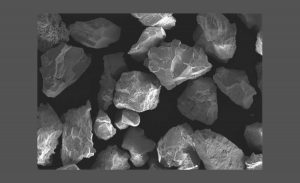

The zirconia prosthesis underwent a series of complex processes before it was put into the patient’s mouth to achieve its chewing, vocal and aesthetic functions, including raw material production of raw material manufacturers, production of zirconia block manufacturers, dental surgeons’ spare tooth mold, processing design, selection of the right zirconium block, cutting, dyeing, sintering, dyeing, polishing, dental doctor’s grinding, etc. As long as one of the above processes goes wrong, it will affect the currently visible quality of the restoration or the currently invisible but potential quality problems in the future.

Zirconium blocks used for all-ceramic teeth can cost anywhere from hundreds to thousands of dollars just from the cost of materials alone. From the above analysis, we can see that the proportion of the raw material cost is not large, but the difficulty of processing leads to an increase in the overall preparation cost.

At present, the forming of zirconia ceramic crowns is dominated by CNC processing technology, which has advantages in product precision and processing efficiency. However, due to the material removal by cutting tools on zirconium plates (blocks) during processing, the cost of ceramic crowns remains high due to the waste of materials and the wear of cutting needles, and microcracks are easily introduced in the cutting process, leading to the failure of the restoration. The current zirconia denture is semi-machined, and the zirconia teeth processed by a professional milling machine need to be used to repair the maxillofacial fossae and furrows with a crack drill or a ball drill to achieve a realistic effect. If human ingenuity is lacking, it can also be said that it has a little personality in shape and edge treatment.

To sum up, the waste of raw materials and the high labor cost of advanced technical workers inevitably increase the preparation cost of zirconia teeth due to the inevitable mistakes in manual processing. Therefore, seeking a new dental ceramic prosthesis forming technology is the characteristic of dental ceramic research and the key point of the clinical prosthesis.