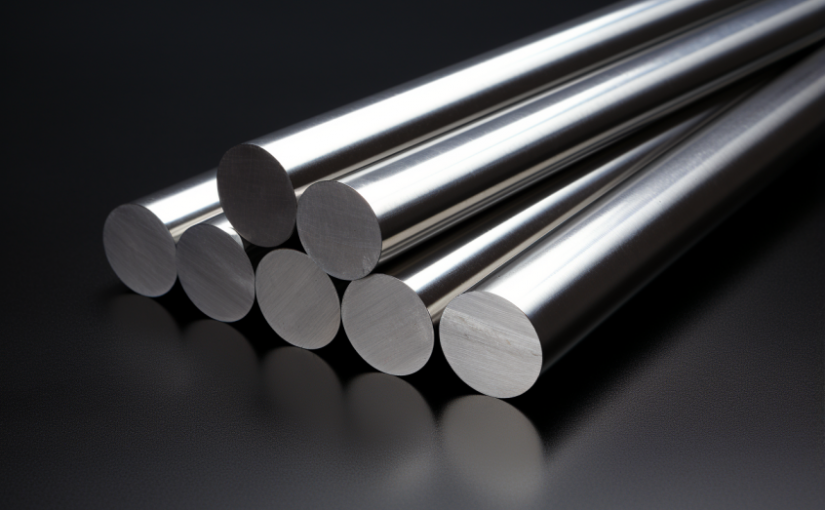

In the realm of nuclear energy, the role of advanced materials is paramount in ensuring safety, efficiency, and sustainability. Among these materials, Zirconium 702 alloys have emerged as a cornerstone in nuclear applications, particularly in the construction of fuel cladding for reactor cores. Let’s delve into the exceptional properties and critical applications of Zirconium 702 in the nuclear industry.

Zirconium 702, a zirconium alloy primarily composed of zirconium with a small percentage of other elements, boasts a combination of properties that make it uniquely suited for nuclear environments. One of its defining features is its low thermal neutron capture cross-section, which minimizes the chances of neutron absorption and subsequent production of undesirable isotopes. This property is crucial in maintaining the stability and controllability of nuclear reactions within a reactor core.

Corrosion resistance is another standout attribute of Zirconium 702 alloys. In the harsh and chemically reactive environment of a nuclear reactor, where extreme temperatures and corrosive agents are prevalent, Zirconium 702’s ability to withstand corrosion ensures the longevity and safety of fuel cladding. This corrosion resistance is essential for preventing the release of radioactive materials into the reactor coolant.

Mechanical strength is a third key factor. Zirconium 702 alloys exhibit impressive mechanical properties, enabling them to withstand the mechanical stresses and pressures experienced during reactor operation. This strength is pivotal in maintaining the integrity of fuel rods and preventing breaches that could lead to fuel leakage.

Zirconium 702 alloys find extensive use in pressurized water reactors (PWRs) and boiling water reactors (BWRs), which represent the majority of commercial nuclear power plants globally. In PWRs, Zirconium 702 cladding encases the fuel pellets, providing a barrier that contains radioactive byproducts and prevents contact with coolant. In BWRs, Zirconium 702 components contribute to the stability and efficiency of the reactor core.

Advancements in Zirconium 702 alloy technology continue to enhance its performance in nuclear applications. Research focuses on optimizing the alloy’s microstructure, refining manufacturing processes, and exploring innovative coatings to further improve corrosion resistance and mechanical durability.

In conclusion, Zirconium 702 alloys have revolutionized the landscape of nuclear energy. Their low thermal neutron capture cross-section, corrosion resistance, and mechanical strength are pivotal in ensuring the safety and efficiency of nuclear reactors. As the world strives for cleaner and more sustainable energy sources, Zirconium 702 alloys remain at the forefront of powering the future of nuclear energy.

For more information about zirconium products, please visit https://www.samaterials.com/.