Zirconium, with its notable properties like excellent corrosion resistance, high melting point, and exceptional durability, is crafted into various forms to cater to specific industry needs. Each form offers unique characteristics making it suitable for particular applications. Here’s a closer look at the different forms of zirconium metals and their distinct uses:

Related Video:

Zirconium: An Extraordinary Metal from Stanford Advanced Materials

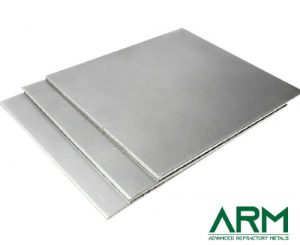

1. Zirconium Plates

Zirconium plates and sheets find widespread application in the aerospace industry, valued for their resistance to high temperatures and corrosion. Manufacturers also prefer them for crafting chemical processing equipment, thanks to their superior resilience against acids and alkalis.

2. Zirconium Pipes

Zirconium pipes and tubes play a crucial role in the nuclear industry. They act as cladding for nuclear fuel rods because they absorb neutrons at a low rate. Their resistance to corrosion also makes them perfect for chemical plant piping systems.

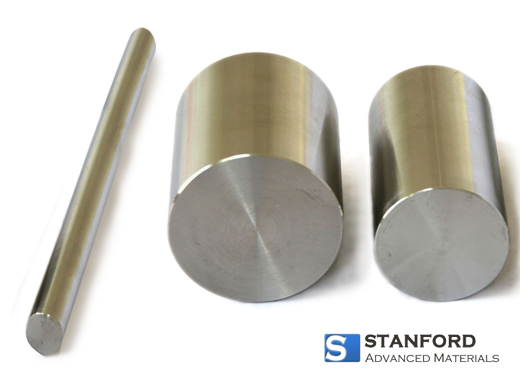

3. Zirconium Bars

Manufacturers use them in surgical devices and medical implants, capitalizing on Zr’s biocompatibility. The automotive industry also relies on them for components that must endure harsh conditions.

4.Zirconium Strips

Zirconium strips are widely used in electronics for their conductivity and corrosion resistance, and in aerospace for their heat resistance. Zr strips also find applications in medical devices due to zirconium’s biocompatibility. Additionally, their ability to be anodized makes them popular in decorative applications.

5. Other Zirconium Products

Zirconium Sponge serves as a primary source for producing high-purity zirconium and its alloys. This transitional form plays a crucial role in the metallurgical process to obtain the metal in its pure or alloyed state.

Zirconium Meshes find use in filtration and sieving, especially in corrosive environments. Their applications also extend to aerospace and medical implants, taking advantage of zirconium’s structural integrity and biocompatibility.

Zirconium Crucibles offer exceptional resistance to high temperatures and corrosion, making them ideal for use in laboratory experiments and industrial processes that require melting or holding highly reactive materials. Their durability and ability to withstand aggressive chemical environments without contamination make them a preferred choice for applications in the chemical analysis, metallurgy, and materials science fields.

Advanced Refractory Metals (ARM) is a leading supplier of a wide range of zirconium products. Their offerings likely include a variety of forms such as zirconium plates, zirconium pipes, zirconium strips, etc. Each product is designed to leverage zirconium’s notable properties, such as high temperature and corrosion resistance, low neutron absorption rate, biocompatibility, and structural integrity. For more details, please check the table below.

Table 1. Zirconium Metals in Different Forms

| Zirconium Product | Applications | Attributes |

| Zirconium Plates | Aerospace industry, chemical processing equipment | High temperature and corrosion resistance, resistance against acids and alkalis |

| Zirconium Pipes | Nuclear industry as cladding for fuel rods, chemical plant piping systems | Low neutron absorption rate, corrosion resistance |

| Zirconium Bars | Surgical devices and medical implants, automotive components | Biocompatibility, durability under harsh conditions |

| Zirconium Strips | Electronics, aerospace, medical devices | Conductivity, corrosion resistance, heat resistance |

| Zirconium Sponge | Producing high-purity zirconium and alloys, metallurgical processes | High-purity production, crucial in metallurgical processes |

| Zirconium Meshes | Filtration and sieving in corrosive environments, aerospace, and medical implants | Structural integrity, biocompatibility, suitable for corrosive environments |

| Zirconium Crucibles | Laboratory experiments and industrial processes for melting/holding reactive materials, chemical analysis, metallurgy, materials science | High temperature and corrosion resistance, durable |

The versatility of zirconium in its various forms allows for its widespread use across multiple industries, including aerospace, nuclear energy, medical, chemical processing, and beyond. This adaptability stems from its remarkable physical and chemical properties, which engineers and scientists continue to leverage in developing advanced technologies and solutions.